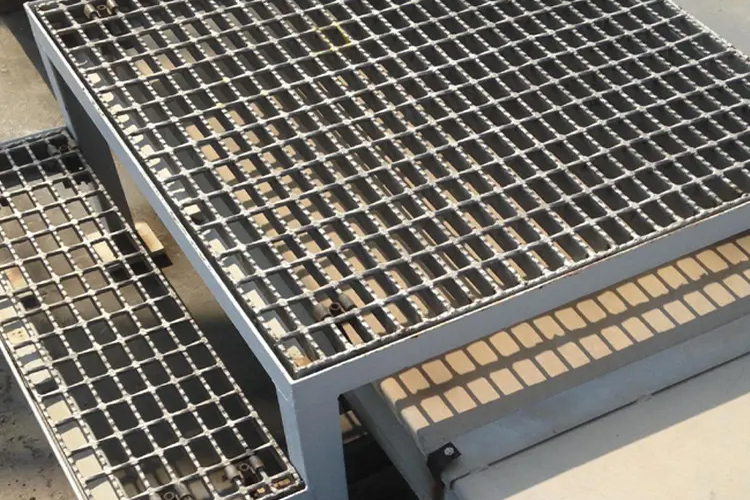

1. The toothed steel grating has large mesh holes and has the best drainage function: the leakage area reaches 83.3%, more than twice that of cast iron. 2. Beautiful product appearance: simple lines, silver appearance, modern concept, 3. Material saving and investment saving: the price of large span and heavy load is lower than that of cast iron; It can also save the cost of replacing the cast iron cover due to theft or crushing. 4. The skid resistance of the toothed steel grating platform is the best among the steel grating types, which can greatly increase the friction of the steel grating surface, avoid accidents due to skidding, and ensure the safety of production to a greater extent.1. Height (or width) and thickness of flat steel of toothed steel grating: the height of flat steel is usually 20mm, 25mm, 30mm, 32mm, 35mm40mm, 45mm, 50mm, etc. The thickness of flat steel of steel grating is 3mm, 4mm, 5mm, 6mm, 8mm, etc; 2. Surface treatment of toothed steel grating: hot galvanizing, cold galvanizing, electroplating, painting, immersion in anti-rust oil, immersion in plastic. 3. Spacing of loaded flat steel of toothed steel grating: the center distance between two adjacent loaded flat steel, usually 30mm, 40mm, sometimes 60mm; 4. The spacing between cross bars of tooth-shaped hot-dip galvanized steel grating: the center spacing between two adjacent cross bars is usually 50mm and 100mm. Special specifications can be produced according to customer requirements.

1. The toothed steel grating has large mesh holes and has the best drainage function: the leakage area reaches 83.3%, more than twice that of cast iron. 2. Beautiful product appearance: simple lines, silver appearance, modern concept, 3. Material saving and investment saving: the price of large span and heavy load is lower than that of cast iron; It can also save the cost of replacing the cast iron cover due to theft or crushing. 4. The skid resistance of the toothed steel grating platform is the best among the steel grating types, which can greatly increase the friction of the steel grating surface, avoid accidents due to skidding, and ensure the safety of production to a greater extent.1. Height (or width) and thickness of flat steel of toothed steel grating: the height of flat steel is usually 20mm, 25mm, 30mm, 32mm, 35mm40mm, 45mm, 50mm, etc. The thickness of flat steel of steel grating is 3mm, 4mm, 5mm, 6mm, 8mm, etc; 2. Surface treatment of toothed steel grating: hot galvanizing, cold galvanizing, electroplating, painting, immersion in anti-rust oil, immersion in plastic. 3. Spacing of loaded flat steel of toothed steel grating: the center distance between two adjacent loaded flat steel, usually 30mm, 40mm, sometimes 60mm; 4. The spacing between cross bars of tooth-shaped hot-dip galvanized steel grating: the center spacing between two adjacent cross bars is usually 50mm and 100mm. Special specifications can be produced according to customer requirements.